Quick Info:

MIDI-plant

Scrap Tire Recycling

|

|

|

|

|

|

|

|

| Dirk Gerlach Engineer

|

|

|

|

|

Upgrading of Scrap Tyres

Target

- Disposal of scrap tires

- Production of a high quality condensates for bitumina and chemical industries

- Production of industrial carbon black; best case substitution of rubber carbon black -> but there are still needed international standards for high quality levels

|

Products

- Permanent gas: for process heating

- Condensate oil: heating value up to 44 MJ/kg

- Condensate water: low amount

- Solids: industrial carbon black typically 80-85% C, rest are fillers

|

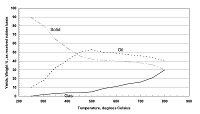

Please find here a diagramm taken from

CalRecovery-Report No. 1364

California 1995:

|

Advantages DGE Basic Technology

- continuous process for highest quality and stability

- no critical emissions

- electrical heat -> minimum of emissions & minimum of heat losses

- combination with renewable energy

- process open for sidestream technologies (catalysts, ultrasonic, microwaves)

Needed Pre Treatment

|

- Drying: not needed

- Pre-Crushing: 250x250mm is possible, 20x20mm typical - but smaller pieces increasing the throughput

- Granulation to 1mm grain

- Sorting: metall separation (non tempered scrap metall gives higher prices)

|

Post Treatment

- Activation

- Milling down to µ-particles

- Pelleting / briquetting

- Fractioning of the oil

Further Information

|

Links

|

|

|

|

Dipl.-Ing.(FH) Dirk Gerlach • Passion for Innovation

|

|  |

|

|

|

|

|

A Service of LEO GmbH.

|