Quick Info:

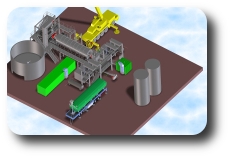

MIDI-plant

Scrap Tire Recycling

|

|

|

|

|

|

|

|

| Dirk Gerlach Engineer

|

|

|

|

|

DGE thermolysis plant MAXI

- fully automatic

- autarc up to 48 hours

- menless shifts possible

- design by DGE 2009-2012

|

|

- Limassol

- scrap tires

- in operation since 07/2009

- design by Dirk Gerlach 2008

|

|

Please note:

Since 2013 we offer the MIDI-plant series. A MIDI-duo plant can operate the same input, but is much more flexible.

Possible Operation

Production Plant

This plant size allows an economic using of pre plants for preparing the raw materials. This can be:

- using of complete scrap tires and preparing by shredder and granulator

- using of wet biomasses and preparing by special drying processes in combination of wet fermenters

- using of fluffy (bio) materials and preparing by pelletizing

Local Energy Supply

- economic using of local resources (biomasses, lignite)

- environmental friendly disposal of local production waste

- hygienisation and thermal disposal of predried (hazardous) sludges

| feeding material |

input energy |

free energy |

energy price |

operating costs |

| Scrap tire granulate (100 €/t) |

1,000kg/h = 9 MW |

oil: app. 4.5 MW

carbon: app. 3.0 MW |

0.022 €/kWh (only oil)

0.013 €/kWh (oil+ gas) |

0.026 €/kWh incl. financing

0.016 €/kWh |

Local allround solution

With the possibility of several feed materials you got an universal solutions for small villages of appr. 400 - 1,000 citizens:

- plastic waste processing for producing a storable heating energy, possible fuel for power generation

- biomass processing for producing fertilizer (ex. g. Tera Preta)

- food rest processing as waste disposal

- soil processing for cleaning the environment (ex. g. mercury contamination of gold production)

- (waste) heat for heating of green houses (food production)

|

|

|

Dipl.-Ing.(FH) Dirk Gerlach • Passion for Innovation

|

|  |

|

|

|

|

|

A Service of LEO GmbH.

|