|

Consulting

You want to hear a further opinion?

With our partners we offer following services:

- Consulting around rotary kiln technologies

- Product preparation before thermolysis

- Product treatment after thermolysis

- Stress calculation of existing indirect heated rotary kilns

- Checking for offers

- Energy-related advisory service

|

Target:

The educt is (not) usable.

Product samples for customer's analysis

|

Step 1: Product testing

You want to check your product for rotary kiln thermolysis?

A first step is to test your product in a rotary kiln at different temperatures. Typically we need for a test set 50 - 100 kg (dry material)

With our partners we can offer following services:

- Rotary kiln lab test up to 10 kg/h

- Analysis of coke/solid

- Analysis of permanent gas

- Analysis of condensate (oil + water)

- Centrifugation of condensate

- Distillation test with GC-analysis

For preparing an offer we need information/analysis about your product (and also from your company).

Here you can ask for an offer by mail.

|

Target:

Documentation for investors.

|

Step 2: Pre-Engineering

The pre engineering includes a first process calculation to get the rough dimensions of the equipment. Due to the budget it also includes:

- Further lab test sets

- Activating tests up to 850 °C

- Condensate separation

- Further destillation and cracking

- Rotary kiln plant test up to 70 kg/h

- Performance test for maximum throughput

- Main Flow sheet

- Process description

- Basic-HAZOP)

- Plant layouts in 2D

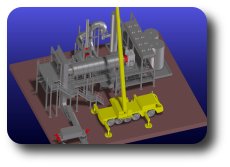

- Rendered plant pictures in 3D

- Budget or fix price offer

For preparing a pre-engineering offer we need information/analysis about your product (and also from your company).

Here you can ask for an offer by mail.

|

Target:

Documentation for authorities.

|

Step 3: Basic engineering

With our partners we offer following services:

- Updating pre-engineering

- Detailed flow sheets

- Mass balances for different operating states

- Product preparation before thermolysis

- Product treatment after thermolysis

- Stress calculation of indirect heated rotary kilns

- HAZOP studies

- Site Specification

- Project time schedule

- Papers for authority

- Layout- and anchordrawings with loads

- Rotary kiln plant test up to 1,000 kg/h

|

Target:

Target:

Detailed informations and drawing for the general contractor.

|

Step 4a: (Preponed) Detail Engineering

To avoid delays we offer in combination with a final contract a preponed detail engineering.

The customer mainly gets:

- Steelwork statics and manufacturing drawings

- Detailed process information

- Order specifications of equipment

- Wireing diagramms and control cabinet design

- ready coded control system

- rapid-prototyping

|

|

Step 4b: Plant manufacturing, erection and startup

The customer mainly gets due to request:

- Machinery

- Transport coordination

- Erection supervision

- Erection crew

- Startup supervision

- Teaching

- Guarantee services

- Maintenance contract

|

|

Further service:

Compact & Semimobile MIDI Plant

The customer gets ready wired & tested compact plant which can easily transported by trucks. The erection time at customer's site is 1 - 2 weeks.

You can start with one line to open the market and latero n you can add up to 3 further lines. This reduces the start invest and gives more safety.

For further information about DGE-Thermolysis-plant click here!

|

|

Teaching

You want to be informed?

With our partners we offer following knowledge:

- Speeches about rotary kiln plants

- Speeches about thermolysis/pyrolysis

- Speeches about complex recycling solutions (ex.g. T-Rec)

- Lectures at schools & universities

|